In the fast‑moving world of automated manufacturing, every millisecond counts. From automotive parts to consumer electronics, the race to deliver high‑quality products faster and cheaper hinges on one often‑overlooked component: the gear motor. While many engineers think of gear motors as simple suppliers of torque, a deeper look reveals that understanding what a gear motor truly does—and how to optimize it—can unlock dramatic gains in speed, precision, and cost efficiency.

Modern automated production lines are essentially intricate ecosystems of sensors, controllers, and actuators that must cooperate in real time. Gear motors form the backbone of this ecosystem, converting electric energy into controlled mechanical motion for conveyor belts, robotic arms, linear actuators, and more. By precisely translating electrical commands into motion, gear motors provide the “low‑level actuation” that drives the entire system.

At first glance gear motors might seem like static, interchangeable parts. However, the real value lies in their performance characteristics—torque, speed, efficiency, thermal behavior, and reliability. Optimizing these parameters allows manufacturers to push their lines closer to the theoretical limits of speed while maintaining quality and safety. In the following sections we’ll explore why manufacturers are paying unprecedented attention to gear motors, how they can be tuned for peak performance, and what this trend means for the future of smart factories.

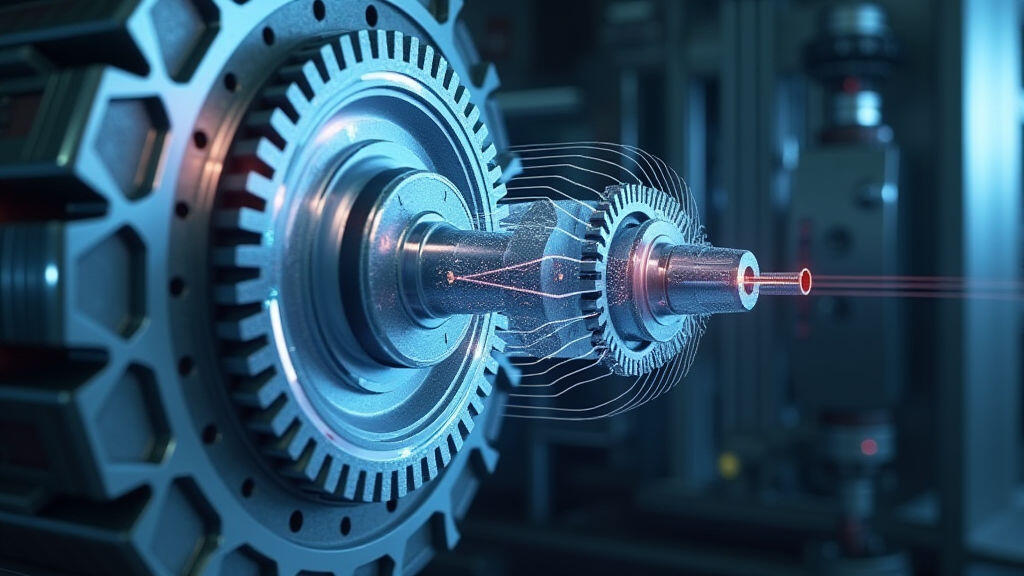

A gear motor typically combines an electric motor with a gearbox. The motor provides the necessary rotational force; the gearbox adapts speed and torque to meet application demands. But the synergy between these two components is where the real magic happens. For instance, a high‑speed motor paired with a finely engineered gear train can achieve smooth acceleration and precise positioning—critical for tasks like pick‑and‑place or high‑cadence assembly operations.

Manufacturers no longer treat gear motors as generic “black boxes.” Instead, they consider:

When manufacturers understand these aspects, they can tailor gear motors to specific line requirements rather than relying on off‑the‑shelf solutions.

Optimizing gear motor performance is akin to fine‑tuning an engine. It involves a mix of analytical tools, real‑world testing, and iterative design. Key strategies include:

Each optimization step requires a detailed understanding of how gear motors behave under specific workloads. For example, in a high‑speed packaging line, the gear motor must deliver rapid acceleration and deceleration without losing torque. Matching gearbox design and motor control becomes a mathematical optimization problem rather than a guesswork decision.

Automotive Assembly Line: A major automotive OEM replaced conventional gear motors with high‑efficiency, closed‑loop models on its welding stations. The result was a 12% reduction in energy consumption and a 5% increase in cycle time reliability. By adjusting gear ratios to match the precise torque needed for each weld, the line achieved smoother motion and lower vibration, which in turn extended the lifespan of weld plates.

High‑Density Electronics Manufacturing: An electronics manufacturer upgraded its pick‑and‑place robots with gear motors featuring embedded brushless DC motors and planetary gearboxes. With real‑time torque monitoring, the robots could adapt to variations in component size and weight on the fly, reducing repeaters and scrap rates by 18%.

These examples illustrate how targeted gear motor optimization turns raw mechanical output into measurable gains—improving both speed and quality.

Digitalization has turned gear motors from static components into data‑rich assets. Edge computing nodes collect motor data, while cloud analytics identify trends across multiple lines. This integrated approach leads to smarter production planning: when a motor shows early wear signs, the system automatically initiates a maintenance ticket before a failure occurs.

Moreover, machine learning algorithms can predict optimal gear ratios for new product designs. Instead of manually simulating scenarios, designers feed product specifications into the system, and it outputs a gear motor spec that balances speed, torque, and energy consumption.

Looking ahead, gear motor manufacturers are investing in self‑diagnostic capabilities, nano‑coated gears for ultra‑low friction, and modular gearboxes that can be reconfigured on the production floor. These innovations extend the gear motor’s role from mere actuators to active participants in the production ecosystem.

Additionally, the push for greener operations drives the adoption of high‑efficiency gear motors that consume less electricity and produce fewer emissions. Combined with renewable energy sources and closed‑loop waste heat recovery, gear motors become key enablers of sustainable factories.

In the quest for faster, cleaner, and more reliable automated production lines, manufacturers must look beyond basic performance metrics. A gear motor is not just a motor with gears; it is a complex, tunable system that dictates how efficiently raw materials transform into finished products. By focusing on what a gear motor truly is—its torque characteristics, energy profile, and integration capabilities—companies can unlock significant improvements in speed, precision, and cost savings.

The trend toward deeper gear motor expertise reflects a broader shift in manufacturing: from isolated, manual processes to interconnected, data‑driven systems. As smart factories evolve, the gear motor’s role will expand from a simple mover to a predictive, self‑optimizing cornerstone of production lines. Embracing this shift promises not only short‑term gains but also long‑term resilience in a rapidly changing industrial landscape.

Leave A Reply

Your email address will not be published. Required fiels are marked